Collections

-

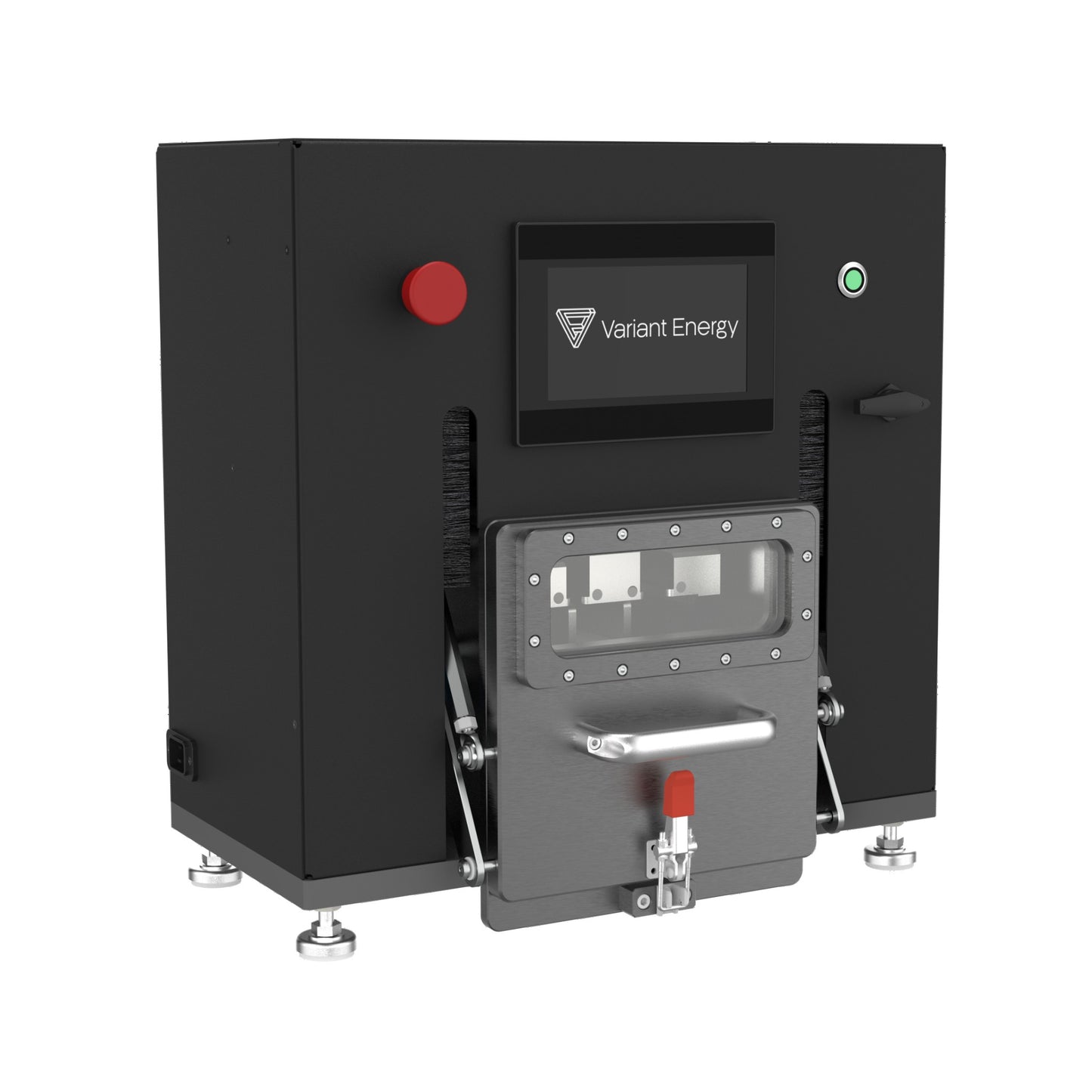

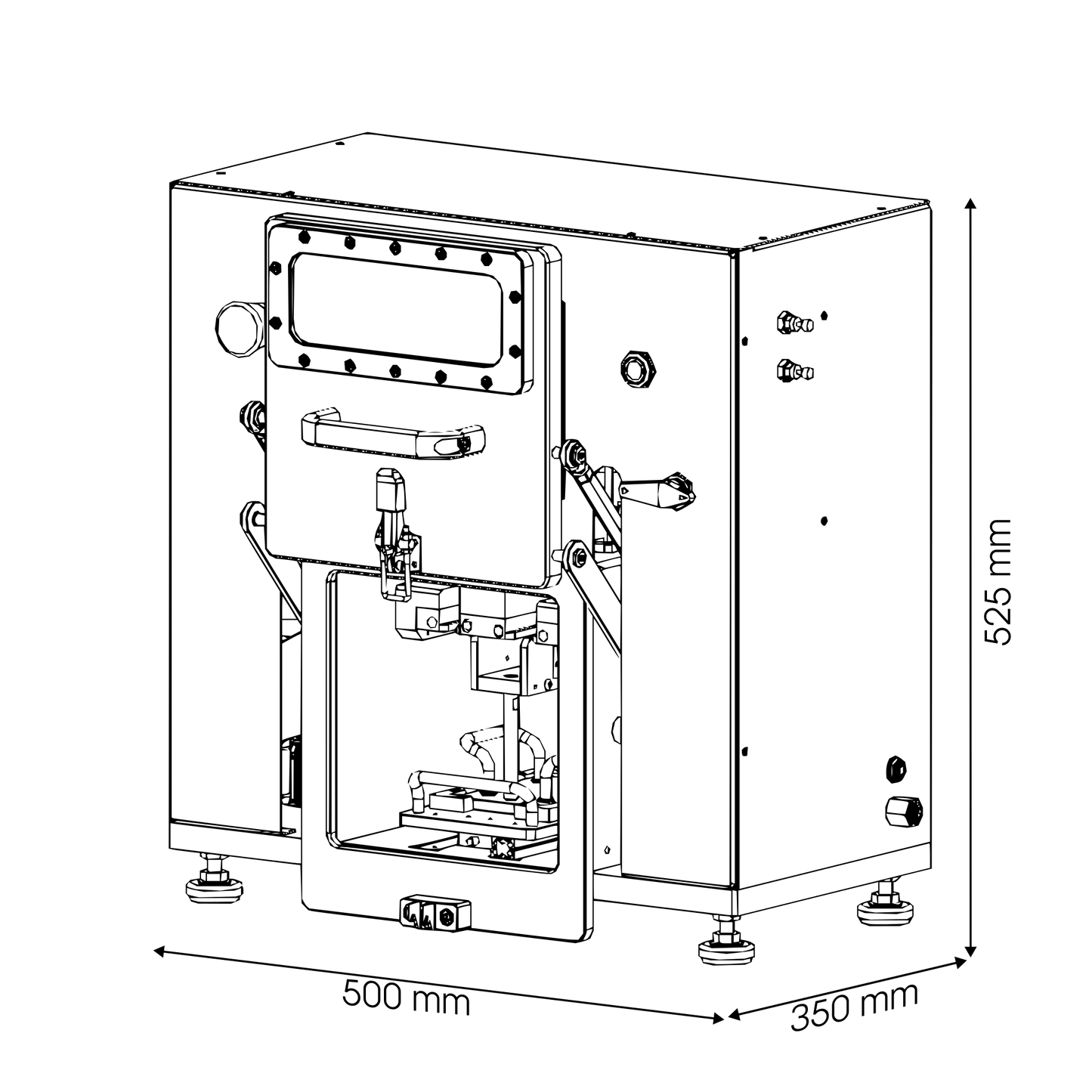

Electrode Coating and Calendering

Produce high-quality electrodes for battery cell energy storage research.

-

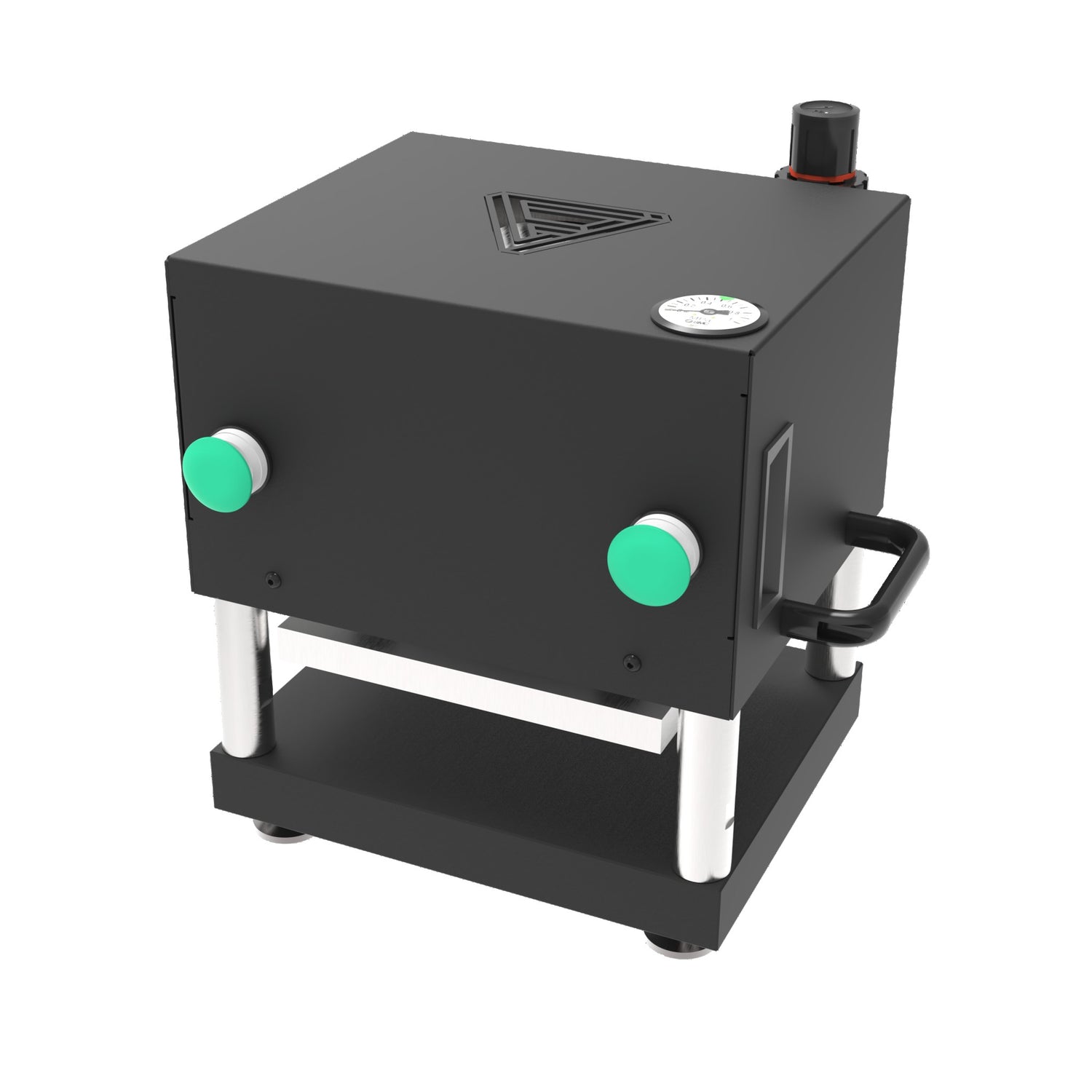

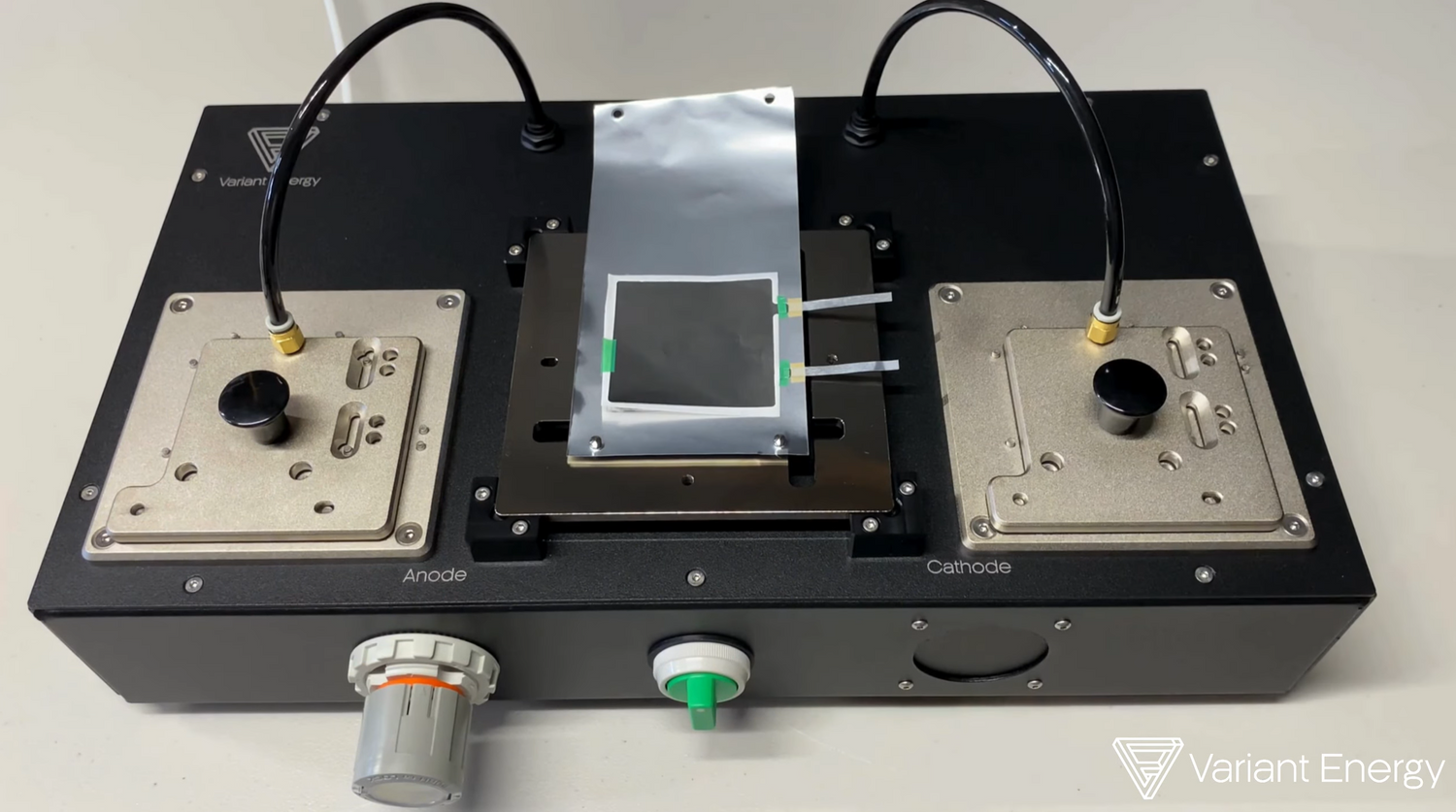

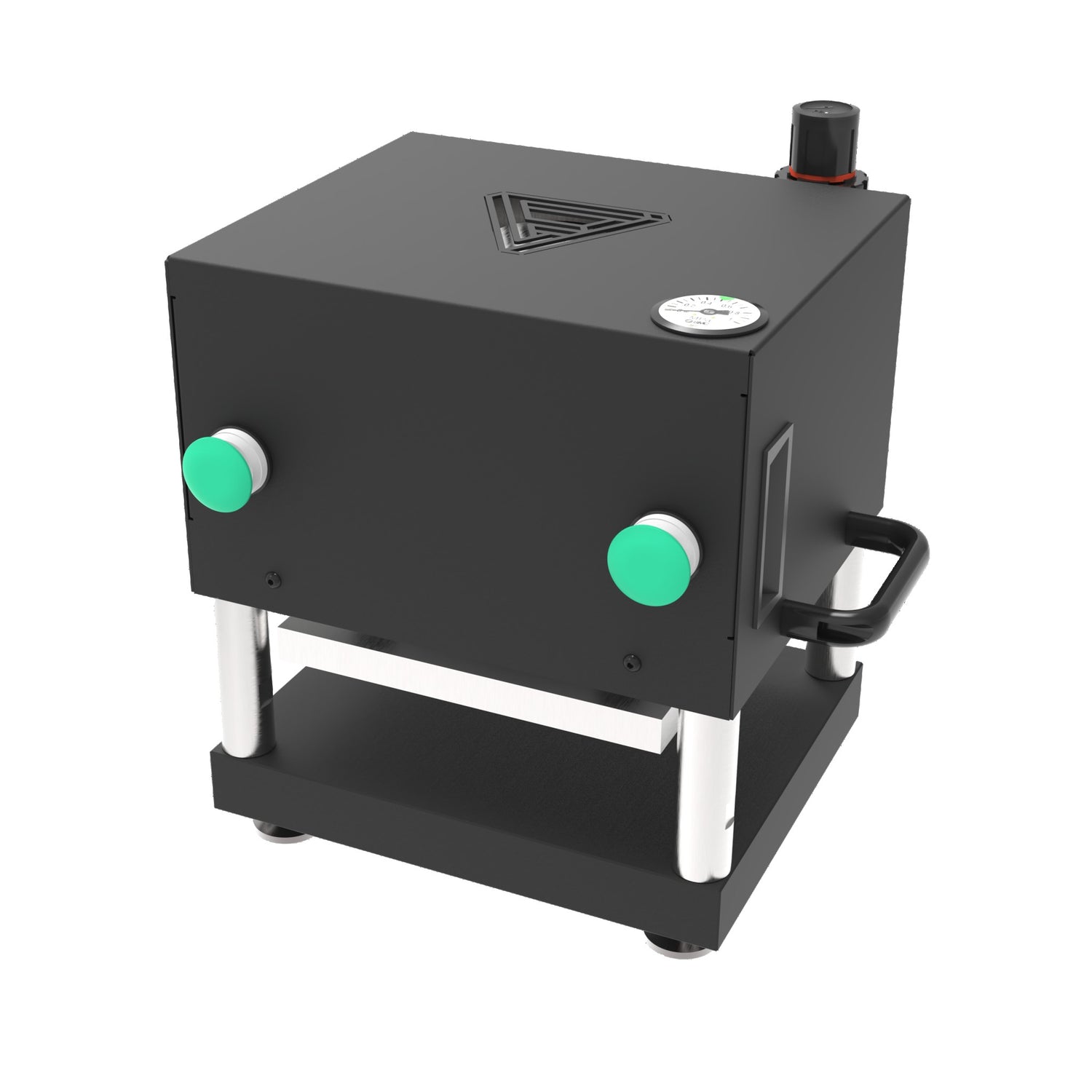

Single Layer Pouch Cell Laboratory Equipment

Take your battery cell research to the next level with Variant Energy's...